WELLE - The Water Footprint of Companies: Local Measures in Global Supply Chains

The aim of the research project WELLE is to develop methodical and practical solutions to calculate the total water footprint of companies.

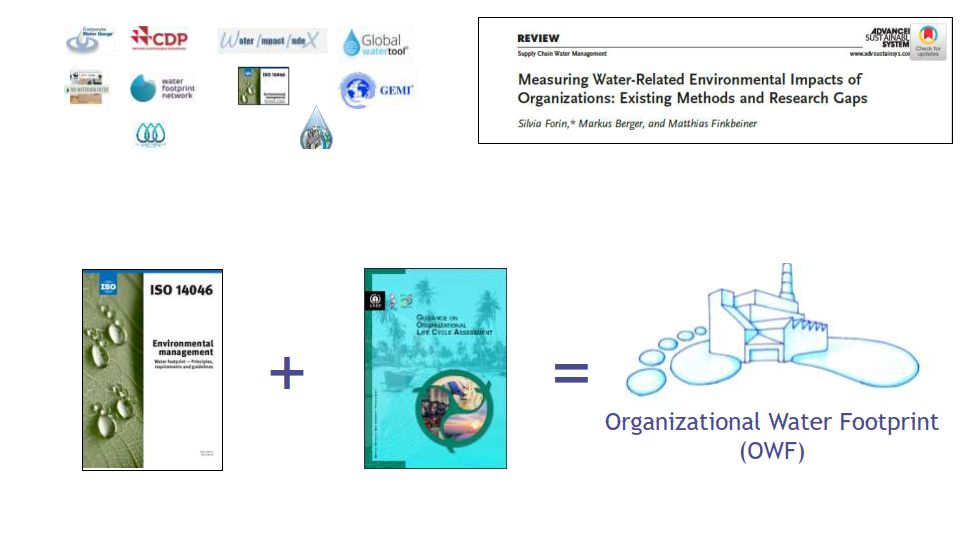

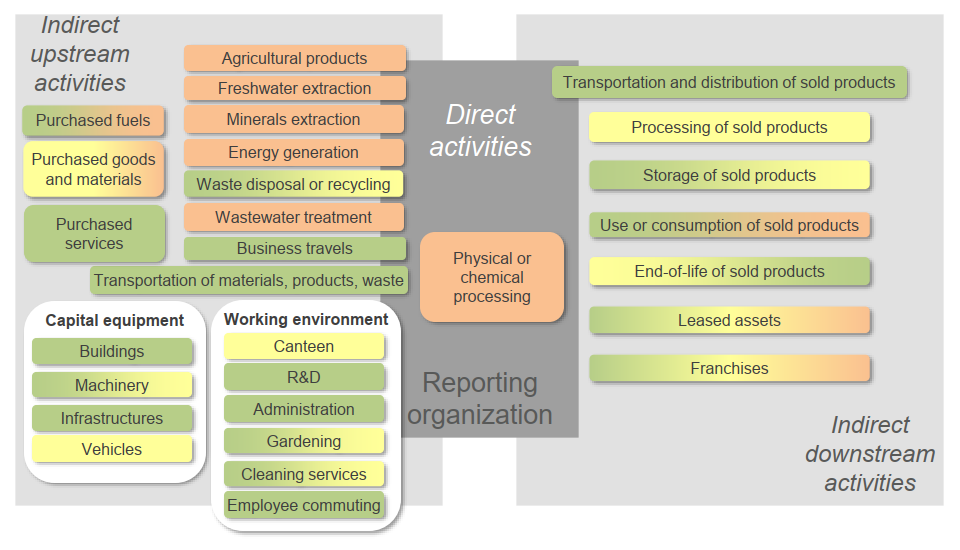

Most products are manufactured in international value chains, which means that a large share of Germany’s water consumption happens outside the country. The water needed to make our products is often consumed in regions of the world where water is extremely scarce. Examples include producing cotton in Central Asia, growing grain in North Africa, and extracting ores in desert regions. At the same time, companies usually only measure and manage their water consumption at their production sites – despite the fact that upstream energy and material chains often use significantly more water. This makes it impossible to identify and reduce the local impacts of water scarcity beyond the production sites. The method for calculating companies’ water footprints will close this gap. By combining the life-cycle assessment method which provides a framework for assessing a company’s environmental impact, and the water footprint method, WELLE will provide companies with a scientifically substantiated instrument, the use of which will be improved by a specific database and related tool. Initiating Water Stewardship measures at the main water scarcity hotspots throughout the supply chain will ensure the transfer of case study results.

Ziel des Forschungsvorhabens WELLE ist es, methodische und praktische Lösungen zur Bestimmung des gesamten Wasserfußabdrucks von Unternehmen zu entwickeln.

Neben dem direkten Wasserverbrauch am Produktionsstandort werden in diesem Ansatz auch indirekte Wassernutzungen in den Energie- und Materialvorketten berücksichtigt. Um diese Methode praktisch anwendbar zu machen, wird ein Leitfaden für Unternehmen entwickelt und eine Wasserinventardatenbank sowie ein Water Footprint Tool zur Berechnung des Wasserfußabdrucks von Unternehmen bereitgestellt. Diese werden zusammen mit Industriepartnern anhand von Fallstudien getestet und so die ersten Unternehmens-Wasserfußabdrücke für verschiedene Branchen erstellt. Der entwickelte Ansatz kombiniert erstmalig eine etablierte Methode zur Bestimmung von Umweltauswirkungen mit einer speziellen Methode zur Bestimmung von Wasserauswirkungen. Nach Einschätzung des Wasserrisikos wird WELLE lokale Hot-Spots identifizieren, in denen Water Stewardship-Maßnahmen durchgeführt werden. Diese sind je nach Ergebnis der Fallstudien voraussichtlich bei Zulieferern in Südafrika, USA, Italien, China, Indien und Chile geplant.

WELLE Presentation(s)

Presentation of the WELLE research project at the GRoW Final Conference 2020 by Dr. Markus Berger. Additional presentations include the WELLE webinar and the WELLE final workshop.

Source: YouTube